Efficiency is key in all aspects of warehouse management, and the pallet rack system you choose plays a huge role in your ability to maximize efficiency. There are plenty of pallet rack options out there, and in this post, we are going to highlight drive-in style pallet rack systems. Let’s discuss how these systems can improve workflow and streamline your warehouse’s processes.

Efficiency is key in all aspects of warehouse management, and the pallet rack system you choose plays a huge role in your ability to maximize efficiency. There are plenty of pallet rack options out there, and in this post, we are going to highlight drive-in style pallet rack systems. Let’s discuss how these systems can improve workflow and streamline your warehouse’s processes.

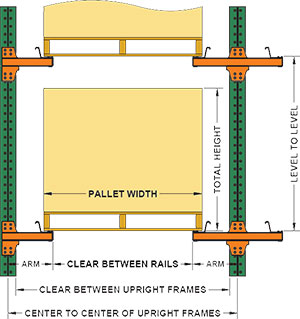

- Better Storage Density. One of the biggest advantages of drive-in style pallet rack storage systems is how they help you make the most of your usable space. The layout allows forklifts to drive into the rack structure and stack pallets on both sides of the aisles, increasing the storage density and allowing you to store more product within a given area, freeing up space you might have otherwise had to dedicate to additional storage.

- Reduced Forklift Travel Time. Navigating a forklift through the aisles of a warehouse can waste a lot of time, but with proper training, your drivers can navigate your drive-in style pallet rack storage systems with ease and efficiency.

- LIFO Inventory Management. Because they are designed with a last-in, first-out system in mind, drive-in style pallet rack storage systems are great for storing homogenous materials that have a high turnover rate.

- Less Aisles. Unlike selective rack systems, drive-in style pallet rack storage systems eliminate the need for multiple aisles. This results in a more compact storage configuration, reducing your overall storage footprint.

Do drive-in style pallet rack storage systems sound like a good fit for your warehouse? Reach out to our team to learn more about them or to inquire about getting this system set up in your warehouse.